The Shipping and Serving Benefits of Foam Packaging

Owing to professional partnership, PRI presents a unique blend of disposable material packaging product services, original automated manufacturing process and advanced shipping practices. PRI’s and its manufacturing collaborators deliver multi-faceted products with customer-satisfying solutions.

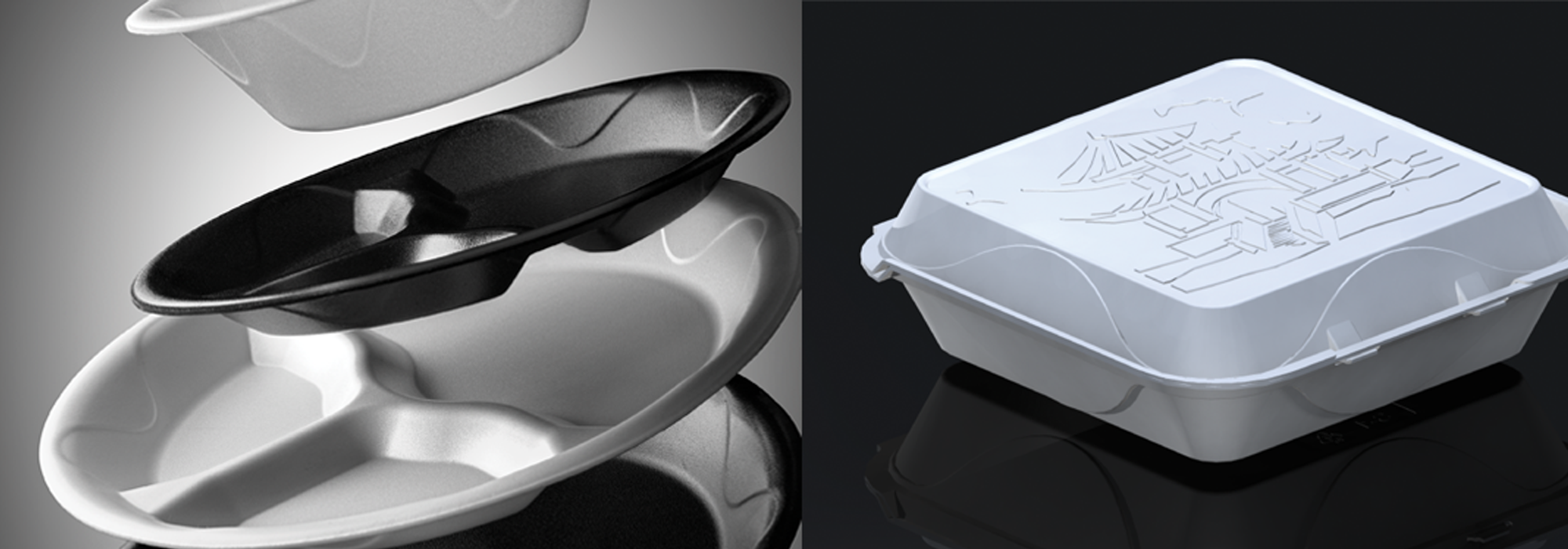

This arrangement of black and white plates, platters, bowls, trays and many convenient items are supported by leading production technology and versatile offering of materials.

Foam, plastic, film and clear packaging comprise one arm of PRI’s represented products. Both square and rectangular hinged lid foam containers (ideal for to go and take out orders) are available to aid all levels of food distribution and retail. Compartmented foam containers give take-out and dine-in flexibility.

With PRI, the line has also made space economy a keen focus in their shipping. A savvy management of fill items and floor-loaded trucks allows the customer’s items delivered intact and at minimum cost.

This line of products has stationed itself at the forefront of the industry by introducing specialty anti-bacterial food wrapping film and dispenser for caterer and restaurant kitchens. It supplies an advantage for every food distributor, caterer, restaurant and retailer.

As a thoroughly forward-minded company, this international plastics manufacturer, and PRI-represented, serves as a leading industry example. In addition to producing above the expectation of the healthy guidelines, this company navigated the market with innovation.

Now producing in a U.S. facility, it has acted as a reliable production facilitation tool with top quality industrial design. These products are defined by a unique pattern for stability and are manufactured for embossing.

Despite the distinctive construction, this PRI-represented brand allows manufacturers to brand its food packaging items with their company identifiers while still getting the reliable quality and convenient delivery of products.

Customers benefit from the fastidious care this company exerts in the earliest production process. With new and sizable manufacturing abilities, a specifically designed cycle ensures that plastics and foam-making are mechanized and never in contact with human hands.

All foam containers and plates, plastic cups and wrap begin as resin and arrive as commercial packaging on the shelf with sound design and safe production.

Comments are closed.